CREMATORY FURNACES Fenice10

The crematory furnaces of the Fenice10 series are indicated to solve small and medium urban centers’ needs and have been specifically designed to perform both a continuous and occasional service minimizing operating costs, consumption and space.

Extremely flexible and compact systems that have been designed to facilitate transportation and simplify installation and assembly procedures.

The management software is equipped with remote assistance and remote control which are essential elements for minimizing maintenance costs and fully automated plant management.

Features of the Fenice 10 model

- Designed to handle large coffins

- Minimal management / maintenance costs

- System vacuum guaranteed

- Redundancy of safety devices and measuring instruments

- Cremation chamber with flat vault

- Compact solution and flexible design

- Fully automated system management

- Teleservice and remote control

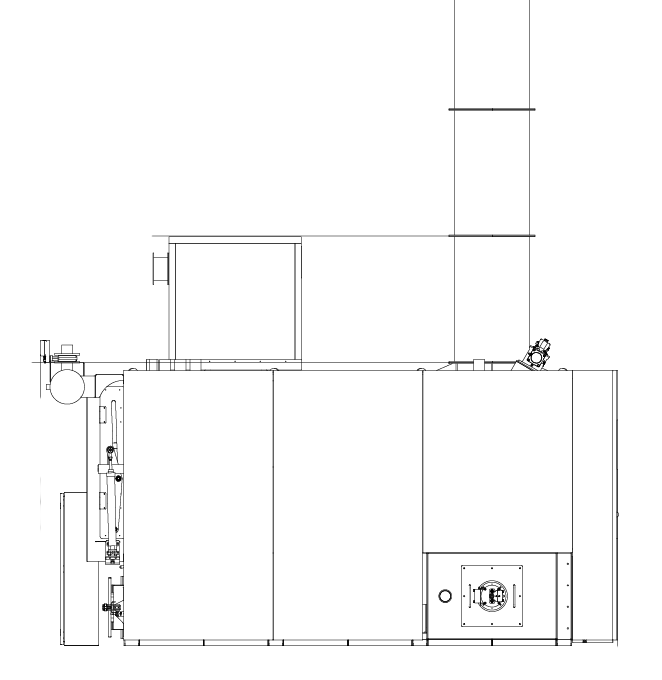

- Front or rear ash discharge

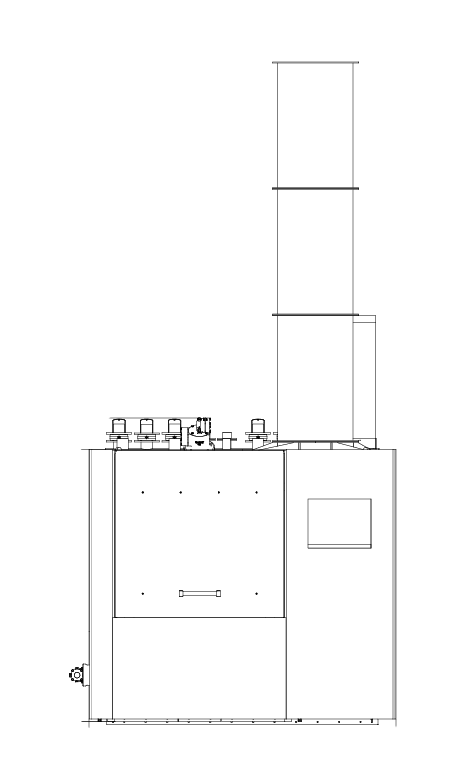

- Self-supporting roof to support the weight of the chimney

- Quick installation

- Dimensions designed to facilitate transport

Product details

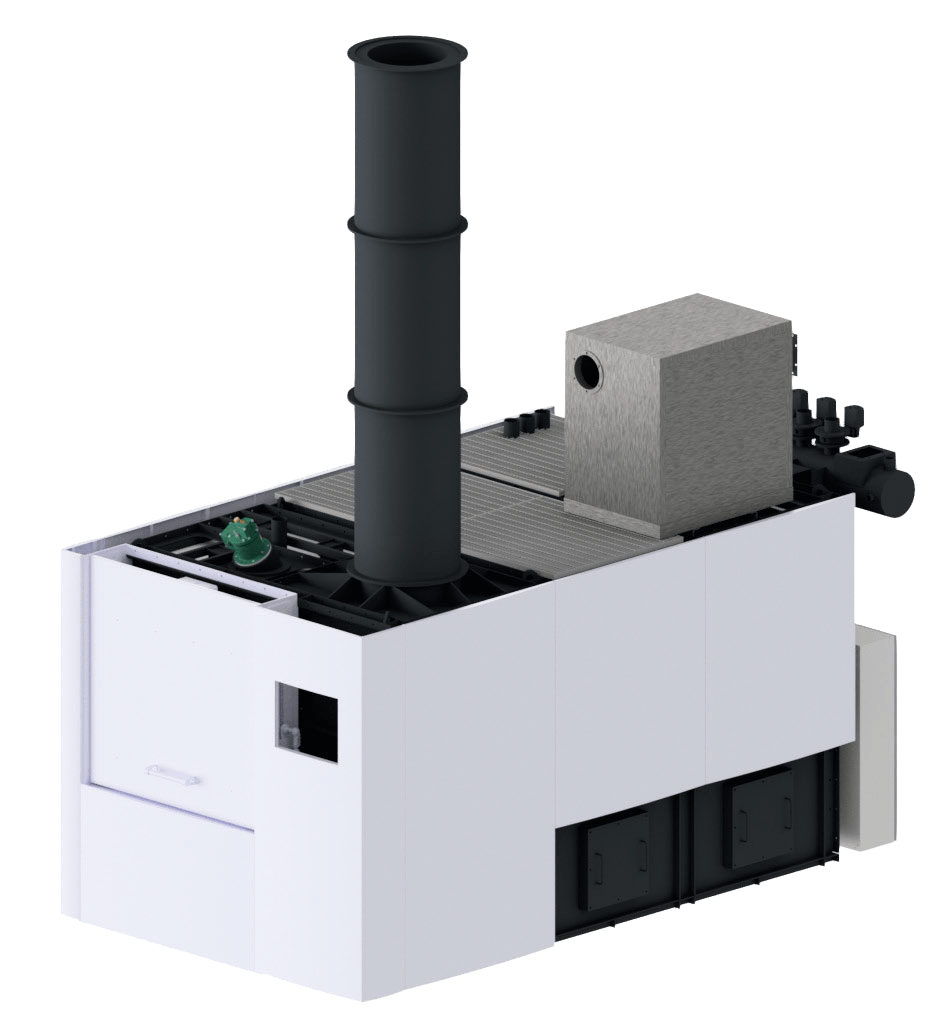

Fenice10 Furnace consists of cremation chamber, flue gas heat treatment chamber or afterburner, cremation sole and calcination and ashes’ recovery system.

The outer shell of the crematorium is entirely made of carbon steel sheet and thick electrowelded metal profiles, suitably arranged to give rigidity to the structure in order to contain and support the refractory and insulating coater as well as the chimney’s weight.

The cremation and the post-combustion chamber are both housed in a single body but are physically separated by a sole made of prefabricated elements and by a refractory masonry vertical partition with passages that allow direct communication between them.

The cremation chamber can also have double end, one for the insertion of the coffin and the other one, on the opposite side, for the extraction of ashes that would be extracted from the introduction door otherwise.

Fenice10 external dimensions have been carefully chosen in order to allow easy transportation within a standard 20’ container, thus reducing shipping costs.

Product Specifications

| CREMATION CHAMBER WORKING TEMPERATURE | |

|---|---|

| Normal | 900 C° |

| Maximum | 1200 C° |

| POST-COMBUSTION CHAMBER | |

|---|---|

| Useful volume | 3.6 m3 |

| Residence time | >2s |

| Normal operating temp | 850+5% C° |

| Maximum working temp | 1200 C° |

| LOADING OPENING DIMENSION | |

|---|---|

| Length | 1000 mm |

| Height | 900 mm |

| TECHNICAL FEATURES | |

|---|---|

| Daily operation | 12 hours/day |

| Average cremation time | 70/90 minutes |

| Fuel | Natural gas/LPG/Diesel |

| Pulp | 15000 kg |

Information request

Contact us to receive information about our products and services or to request a personalized quote.

The Vezzani Cremation team will answer you as soon as possible.