BALL-TYPE CREMULATOR

The ball-type cremulator’s function is to completely pulverize the inhomogeneous ashes, which dimensions and/or aggregates would be incompatible with the final container, admitting the transfer to the funeral urn.

The system consists of a steel ball grinder arranged inside a rotating basket with side holes for the exit of the product which is collected, through a hopper, in the urn.

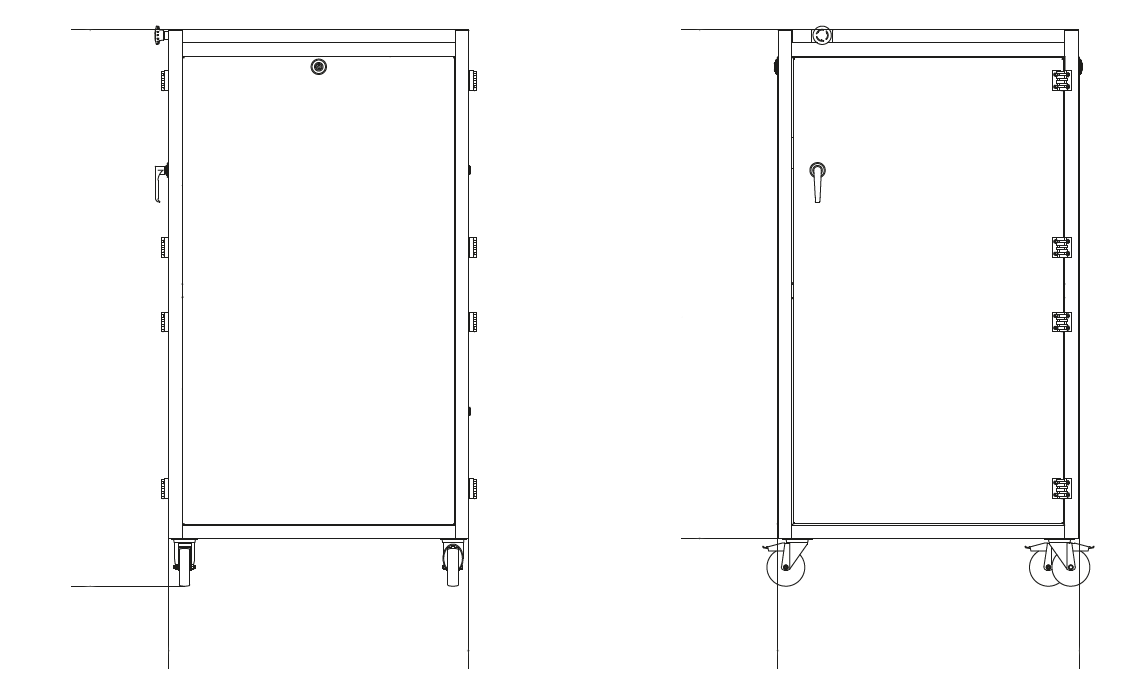

Since the transfer of pulverized ashes is carried out automatically as a result of their crushing and their passage through the sieving sieve, there is no need for any other accessory device meant to transfer ashes into the urn. A soundproof cabinet contains and isolates the internal mill.

Features ball pulverizer

- Collection of ashes directly in the urn

- Processing speed

- Essential and pleasant design

- Stainless steel finishing

Product details

The ball-type cremulator consists of a steel ball grinder arranged inside a rotating basket with holes where the product exits and is collected in

a special container through an hopper.

A soundproof cabinet contains and isolates the internal mill that is elastically suspended from the supporting structure.

Containment cabinet walls and door are isolated from vibrations and noise to maintain noise level well below the limits prescribed by current legislation.

A socket situated on the side of the cabinet connects to an aspirator to capture and destroy any portion of dust that should pass beyond the sealing gaskets of the mill during crushing.

This aspirator inside the unit keeps the grinder cabinet in depression preventing dust from escaping by sending volatile powders to a filter bag and to the collection bag located in the lower part.

The grinding cycle, which can normally be completed within a maximum of 5-15 minutes, has an adjustable duration and can be set on the timer that is situated in the electrical power supply panel.

This in order to adapt to every possible request.

Product Specifications

| TECHNICAL DATA | |

|---|---|

| Dimensions | 990x990x1830 mm |

| Maximum rated power | 15 kW |

| Frequency | AC 50 Hz |

| Diet | 400V |

| Empty weight | 300 Kg |

Information request

Contact us to receive information about our products and services or to request a personalized quote.

The Vezzani Cremation team will answer you as soon as possible.