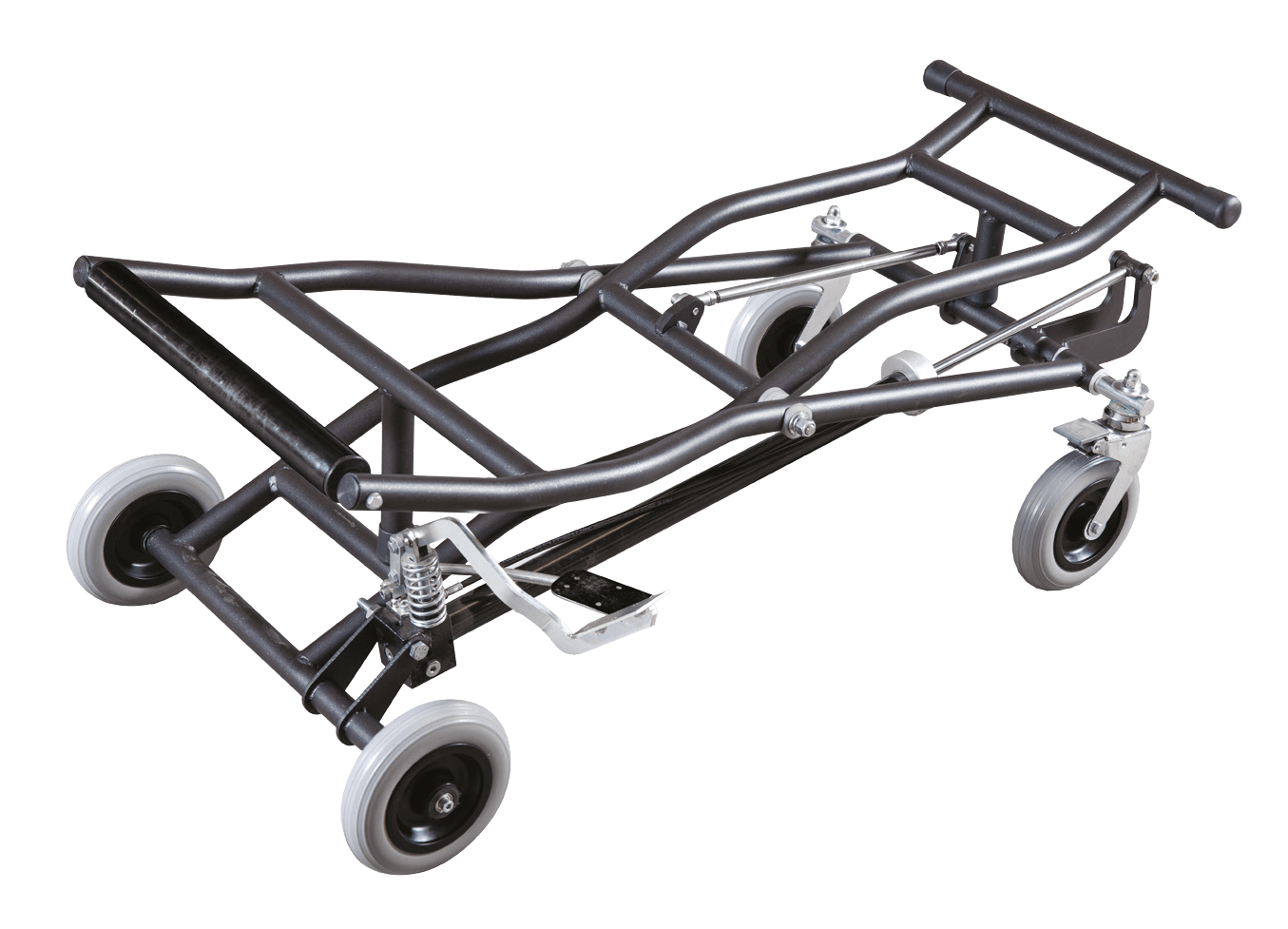

Hercules TROLLEY

The HERCULES cargo transport trolley is suitable for handling loads in storage and storage areas as well as unloading from hearses or other vehicles.

The use of quality materials together with high technology adopted and long experience of VEZZANI FORNI have led to a product with innovative features and high reliability.

Specialized technicians carry out rigorous checks during construction and made accurate final test on each unit.

Features Hercules trolley

- Support frame

- Four wheels 200 mm

- Hydraulic piston with pedal for height adjustment

- 1 rotating roller

- Load braking system

Figure 1

Figure 2

Figure 3

Figure 4

Product details

The product is built entirely in steel and is equipped with:

• hydraulic piston, which guarantees precise lifting at the desired height and in complete safety;

• two fixed wheels and two swivel wheels equipped with brakes, which give the product a better maneuverability;

• 1 support roller with anti-slip material coating;

• Rubber tips for supporting the load.

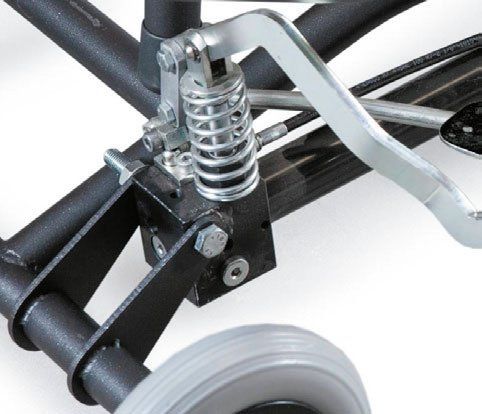

The axis of the pivoting wheels is kept horizontal, even during lifting, thanks to a central tie rod that

keeps the angle to the floor constant.

The angle of the wheels is already adjusted at the time of assembly, if it is necessary to restore this angle, it is necessary to act by loosening the 2 locknuts on the ball joints and rotating the tie rod. After having found the ideal height, fix the locknuts again to lock the system (figure 1).

The lifting pedal (figure 2 - letter A) allows the trolley to be raised to the operating height.

To move, press the pedal downwards: each press will rise the trolley, until reaching the end of the piston stroke.

The descent rod (figure 2 - letter B) allows the carriage to descend.

To move, press and hold the rod until the desired height is reached; the piston will unlock when it has reached the maximum allowed extension.

The two swivel wheels, in opposite positions, are equipped with a lever-operated parking brake device (figure 3 - letter C), in order to effectively

block the trolley during parking.

The engagement of the brake is obtained by pushing the lever (C) downwards.

Its disengagement is obtained by pulling the lever (C) upwards.

To adjust the descent speed of the carriage, use a hexagonal male key of 5, insert it into the appropriate hole (figure 4 - letter D) located in correspondence with the pump adjustment screw: move the key as desired.

Product Specifications

| TECHNICAL DATA | |

|---|---|

| Maximum length | 1300 mm |

| Minimum length | 870 mm |

| Length | 640 mm |

| Max height | 1100 mm |

| Minimum height | 460 mm |

| Movement wheels diameter / thickness | 200/50 mm |

| Pulp | 36 Kg |

| Maximum capacity | 200 Kg |

Information request

Contact us to receive information about our products and services or to request a personalized quote.

The Vezzani Cremation team will answer you as soon as possible.