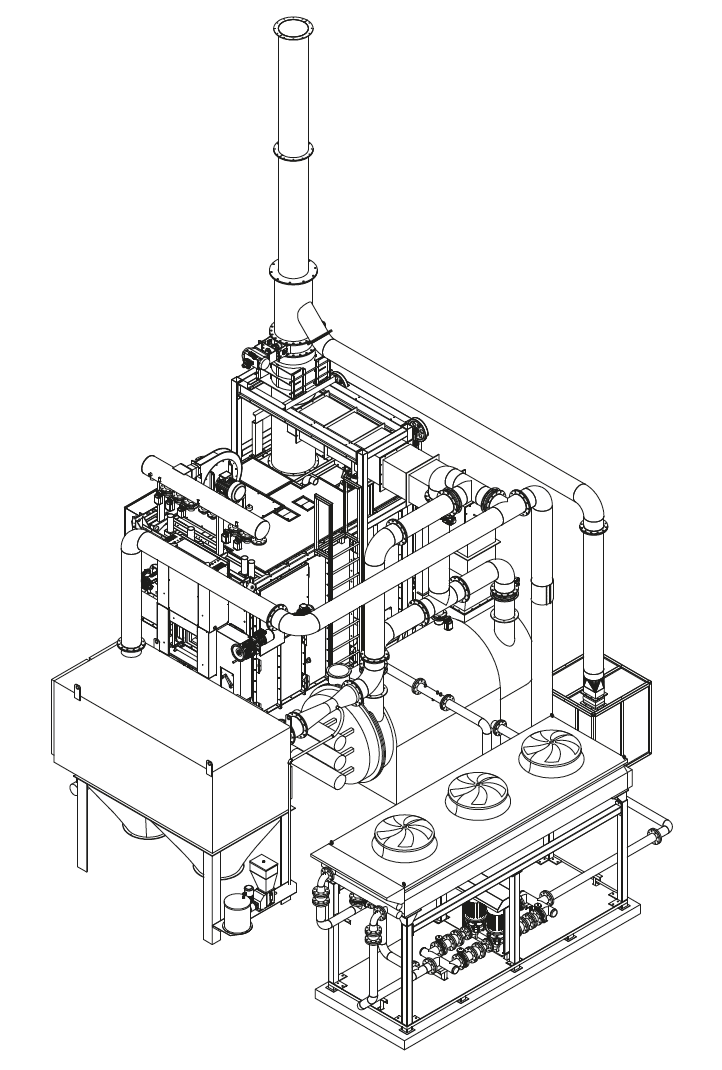

COOLING AND FUMES FILTRATION SYSTEM

The aim of the fumes filtration system is to reduce the pollutant content to values compatible with the ones accepted by the supervisory authority.

The fumes coming out from the afterburner, before they are expelled in the atmosphere, are purified through a chemical-physical treatment.

The fumes coming out from the afterburner reach a temperature higher than 850 C, so they have to be cooled down until they reach temperatures compatible with the regular functioning of the bag filter.

Product details

The cooling system is composed by an air/water heat exchanger structured in order to allow on one side the temperature reduction of the fumes in transit, on the other recycling of the thermal energy taken away from the fumes.

The heat exchanger has a tubular shape (shelland- tube heat exchangers), with a three-phased horizontal configuration and it is equipped with entries designated for inspections and hand cleaning, which can be done depending on the machinery use.

The entire structure is adequately insulated outwards through a mat made of insulating material in high density mineral wool, externally protected with an aluminium sheet; the wall of the smoke chamber in contact with the gasses that have to cooled down are protected with a refractory and insulating concrete lining.

The fumes coming from the afterburner, properly cooled down through the above-mentioned processes, before their discharge in the atmosphere, undergo a chemical-physical treatment aimed at reducing the content of pollutants to values lower that the ones forecast by the National (Italian) legislation.

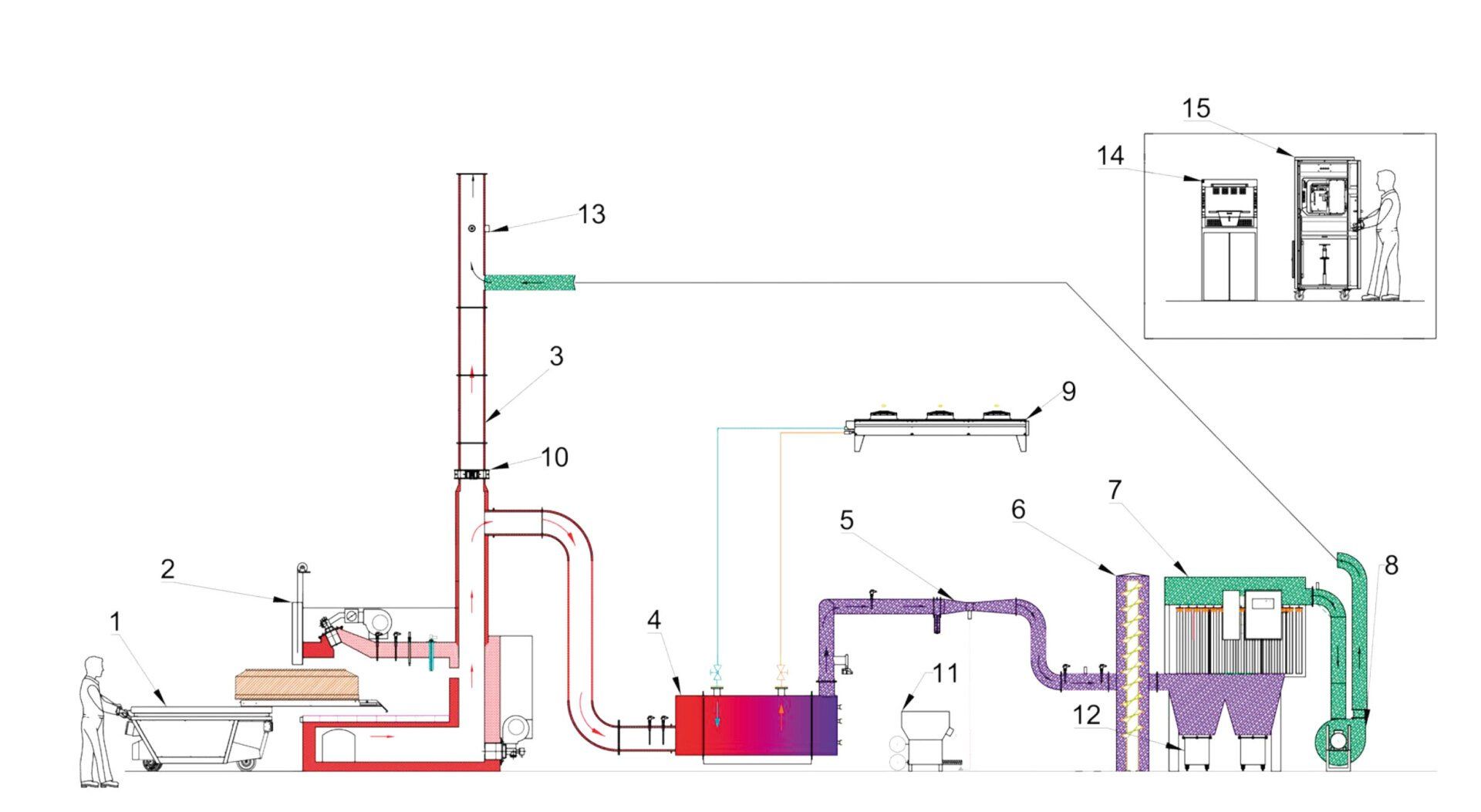

1. Automatic coffin loader

2. Cremation mouth

3. Process and emergency chimney

4. Air / water exchanger

5. Venturi tube

6. Reactor

7. Bag filter

8. Suction fan

9. Dry Cooler

10. Emergency valve

11. Reagent dosing station

12. Exhausted reagent collection drum

13. Sampling point

14. Bench aspirated

15. Pulverizer

The fumes purification system presents three stages of pollutant emission abatement that, together with the thermal afterburner mentioned above, constitute the “Best Available Technology” (BAT)

concerning the performances that are usually requested in case of corpses and mortal remains’ cremation.

The first stage consists in the injection in the fumes’ flow of a reagent mix able to break down acid substances and absorb heavy metals and dioxins/furans.

In the second stage, downstream of the injection and upstream of the bag filter, a reaction chamber is inserted, which uniformly mixes the reagents in the gas flow increasing the time of contact.

In the third stage there is the bag filter, which takes care of the fumes filtration by blocking the solid particulates and used reagents.

The bag filter let the fumes go through the filter at a crossing speed that, compared to a relatively modest pressure drop, has a filtration efficiency higher than 99%.

Optional

- Abatement system SNCR for Nox (NOR20) reduction

- Heat recovery system RC20

- Heat exchanger self-cleaning system

- Continuous monitoring of emissions (SME)

Product Specifications

| SMOKE - WATER HEAT EXCHANGER | |

|---|---|

| Guy | A smoking pipes |

| Max inlet flow rate | 1500 Nm3/h |

| Maximum potential | 440 kW |

| Smoke inlet temperature | 950 °C |

| Flue gas temperature at outlet max. | 180 °C |

| Pressure drops on the flue gas side | 40 mm c.a. |

| Water inlet - outlet temperature | 70 - 80 °C |

| SMOKE DISSIPATOR - AIR (DRY COOLER) | |

|---|---|

| Guy | Conventional on finned tube coil |

| Max. | 600 KW |

| Nominal potential | 440 kW |

| Air inlet design temperature | 37 °C |

| Air outlet temperature | 64 °C |

| Water inlet temperature | 80 °C |

| Water outlet temperature | 70 °C |

| Fans provided | 3 n. |

| Total installed electrical power | 1.8 (x 3) kW |

| System circulation pumps | 2 (twin) n. |

| Pump electric power | 4 (x 2) kW |

| Smoke treatment system FILTRATION DEVICE | |

|---|---|

| Guy | Sleeveless |

| Filter medium | Nomex teflonato |

| Filtering surface | 440 kW |

| Filtration speed @ 180 C | 0.75 m / min |

| Operating temperature | 130 ÷ 170 C |

| Capture efficiency | 99,5% |

| Cleaning system | Compressed air |

| Air pressure | 6 bar |

| Average compressed air consumption | 10 Nm3/h |

| System circulation pumps | 2 (twin) n. |

| Pump electric power | 4 (x 2) kW |

| SMOKE SUCTION FAN | |

|---|---|

| Guy | Centrifugal with backward blades |

| medium range | 3.500 m3/h |

| Head at 20 ° C | 700 mm c.a. |

| Average absorbed power | 6 KW |

| Installed power | 11 KW |

Information request

Contact us to receive information about our products and services or to request a personalized quote.

The Vezzani Cremation team will answer you as soon as possible.